A Legacy of Reliability in Snow Groomer Track Belts

For over four decades, MTN Equipment has built its reputation as a trusted leader in replacement snow groomer track parts across Canada and the northern U.S. While many of our clients know us for our drags, replacement snow groomer tracks, and top-tier service, one of the strongest contributors to our success is often unseen: our long-standing partnership with Artemis, the German manufacturer behind the industry’s most dependable replacement snowcat track belting.

This is more than a vendor relationship; it’s a technical alliance forged through shared standards, product evolution, and a relentless pursuit of quality. And it’s a legacy that continues to support ski resorts, cross-country ski centres, and snowmobile trail systems across North America.

About Artemis

ARTEMIS Kautschuk und Kunststoff, based in Hannover, Germany is a specialist in elastomer and polymer processing, supplying highly engineered rubber and plastic components and systems to a wide range of industrial sectors.

From LMC to MTN Equipment: The Foundation of Trust

Our partnership with Artemis began even before MTN Equipment existed. In the 1980s, our founder, Charles Stenger, worked as a dealer for Logan Machine Company (LMC), a Utah-based manufacturer known for its grooming machines. LMC sourced belts from Artemis, and Charles recalls those early days clearly: “The Artemis belts were reliable and there were never any issues.”

As LMC began winding down operations, Charles saw the writing on the wall—and an opportunity. With thousands of machines still in service across Canada and the U.S., the market was facing a serious parts gap. Charles stepped in to fill it, launching MTN Equipment with a focus on the same Artemis belts that had already proven themselves reliable in the field.

The initial contact with Artemis came through Jeff Gillis, a U.S. ski industry veteran who was then representing Artemis in North America. After visiting MTN in Canada, Gillis recognised the scale of the opportunity and eventually relocated to Germany, where he now serves as Managing Director of Artemis. Over the years, Gillis has remained an instrumental figure, helping to solidify a partnership that has lasted more than four decades.

That relationship didn’t just survive—it evolved. MTN’s growing demand led Artemis to improve their products in direct collaboration with us. For example, earlier belts used cotton ply, which absorbed moisture and weakened over time. Artemis responded to our feedback by switching to a nylon ply for enhanced tensile strength and moisture resistance. This seemingly small shift drastically improved product durability.

Another milestone came in 2019 when Artemis introduced a sealed cap edge on their belts. Just like any prototype, early versions had minor quality issues, but MTN's input helped Artemis refine the sealing process. Today, the vulcanised cap edge is fully integrated and praised by ski hills and trail operators alike for its added durability.

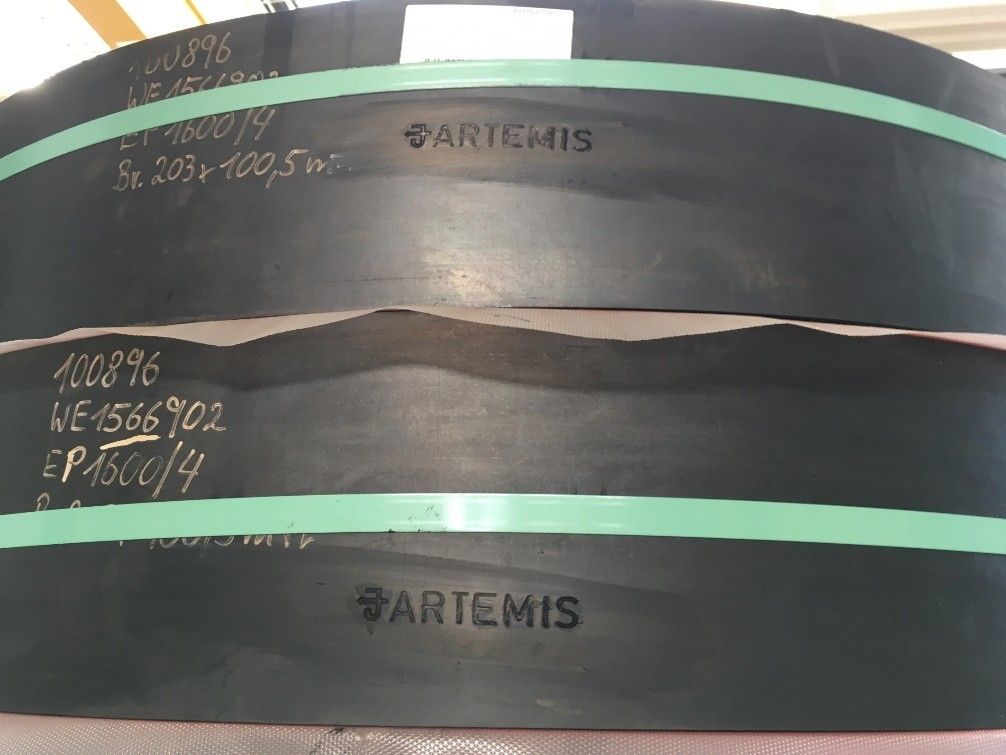

And the innovations didn’t stop there. Artemis now brands belts with MTN’s name and toll-free number—an important move for traceability, customer confidence, and service quality. This unique co-branding initiative underscores the mutual trust and alignment between our two companies.

“MTN Equipment is our largest buyer of rubber belts in the snow-cat industry, and they pair that scale with real foresight by investing in inventory ahead of the season so operators get parts fast and keep their clients’ machines running smoothly.”

— Mr. Jeffrey Gillis, ARTEMIS

Despite competitors offering promises, Artemis remains our belt of choice. The material quality, customer service, and consistency are unmatched. In fact, we maintain a large quantity of Artemis belt inventory in Montreal to ensure immediate shipping is available during peak season.

This commitment to reliability is essential in snow grooming, where breakdowns can derail entire operations. It’s why we continue to invest in this partnership and why Artemis belts are used on nearly every MTN-manufactured track.

“With Artemis, we’re not buying a commodity; we’re cooperating on highly engineered rubber-fabric belts that hold tension, shrug off wear, and perform season after season.”

— Charles Stenger, MTN Equipment

We’ve also contributed feedback to improve production processes—such as belt widths, splice options, and tensile strength upgrades. This collaborative development has made Artemis a leader not just in agriculture and oil industries, but also in snow grooming.

What Makes Artemis Snowcat Track Belting Superior

Unlike off-the-shelf belts, Artemis snow groomer track belts are purpose-built for high-stress, cold-weather performance. At the core of their manufacturing is a one-step vulcanisation process, which creates a sealed-edge, single-structure belt. This seamless method prevents delamination and water intrusion, ideal for freeze-thaw conditions found on trails and slopes.

Key Advantages:

- One-Step Vulcanisation: Prevents edge failures and delamination

- Sealed Edges: Superior water resistance and durability

- Polyester-Polyamide Reinforcement: Balanced flexibility and strength

- Precise Pitch Control: Ensures accurate cleat alignment and consistent traction

These aren’t just features—they’re mission-critical for reliable snow grooming.

Real-World Strength: Ply Count vs. Tensile Strength

| Ply Count | Artemis Tensile Strength (N/mm) | OEM Equivalent (approx.) |

|---|---|---|

| 3-ply | ~1,200 | ~600 (Goodyear) |

| 4-ply | ~1,600 | ~800 (Goodyear) |

See all Artemis snowcat belt specifications

Performance Benefits:

- Reduced Downtime: Fewer breakages, more grooming hours

- Lower Total Cost of Ownership: Longer belt life, fewer replacements

- Consistent Trail Quality: Maintains cleat alignment and surface finish

Supporting Alpine Ops and Volunteer Clubs Alike

For facility managers, downtime is unacceptable. MTN stocks Artemis belts year-round at our Montreal facility to ensure immediate availability.

For snowmobile clubs led by volunteers, affordability matters. MTN offers:

- Custom drilling for older or lesser-known groomers

- Support for LMC, Thiokol, and legacy trail machines

Engineered Compatibility: Pisten Bully, Prinoth, and More

Our belts are compatible with all major snowcat models:

- Pisten Bully

- Prinoth

- Tucker Sno-Cat

- Legacy LMC

We custom-drill to spec based on machine model, cleat spacing, and ply requirements.

Proven Performance in Harsh Environments

Artemis belts are derived from high-durability agricultural belting. Key properties include:

- Abrasion resistance

- Cold-weather resilience

- Low stretch under high loads

This crossover engineering ensures belts perform reliably under:

- Sub-zero temperatures

- Variable terrain

- Extended use seasons

When to Replace Your Snow Groomer Track Belt

Watch for these signs:

- Delamination

- Cracks or tears near cleats

- Belt stretching or misalignment

- Edge fraying

Don't wait until failure—plan preseason replacements for peace of mind.

How to Order a Replacement Snowcat Track Belt

- Identify your machine brand and model

- Confirm belt width and cleat layout

- Select ply and tension specs

- Request a quote via our online form

FAQs

Are Artemis belts compatible with Prinoth and Pisten Bully groomers?

Yes. We offer custom-drilled Artemis belts compatible with all major snowcat brands.

How long do Artemis belts typically last?

4–6 seasons on average, depending on use, terrain, and maintenance.

Can I order belts in the off-season?

Absolutely. We stock belts year-round and recommend preseason orders.

What’s the difference between 3-ply and 4-ply belts?

4-ply belts offer higher tensile strength and are best for high-usage or hilly terrain.